Have you ever wondered how casino chips are made? These tiny gaming components play an integral role in the casino industry, acting as currency within a gaming environment. From the design concept to the manufacturing process, each chip undergoes thorough scrutiny to ensure it meets strict quality and security standards.

In this section, we’ll take a closer look at the intricate process involved in making casino chips. From the materials used to the final product, you’ll discover the fascinating world behind casino chip production.

Key Takeaways:

- The casino chip manufacturing process involves a series of intricate steps to create small but significant components of the gaming industry.

- The materials used, design concept, and manufacturing techniques all play crucial roles in producing high-quality and visually appealing casino chips.

- Quality control and security measures are essential to ensure the chips meet the required standards and address potential security concerns.

- Understanding how casino chips are made provides a deeper appreciation for the attention to detail and effort involved in their production.

Casino Chip Materials

When it comes to casino chip manufacturing, the choice of materials is crucial. The materials used affect the weight, durability, and overall feel of the chip. Let’s take a closer look at the most commonly used materials and the fabrication process involved in creating casino chips.

Ceramic

One of the most popular materials used for high-end casino chips is ceramic. Ceramic chips are made through a process called compression molding, where a ceramic powder is compressed into the desired shape using a mold. The chips are then baked at a high temperature to harden the ceramic, resulting in a durable and solid product. Ceramic chips have a smooth texture and are often heavier than other materials, providing a satisfying feel when stacking chips.

Clay Composite

Another popular material for casino chips is clay composite. Clay composite chips consist of a mixture of clay and other materials, such as plastic or resin. The mix is then molded into the desired shape and design using compression or injection molding. The chips are then typically coated with a protective layer to prevent fading or wear. Clay composite chips are popular for their classic look and feel, and they are often used in lower stakes games.

Plastic

Plastic chips are the most affordable option for casino chip manufacturing. They are typically made using injection molding, where melted plastic is injected into a mold to create the chip shape. Plastic chips are lightweight and often have a textured surface for easy stacking. While they are not as durable or aesthetically pleasing as other materials, plastic chips are commonly used in casual settings and for promotional purposes.

Overall, the choice of material depends on the desired quality and usage of the casino chip. Manufacturers must consider the functionality, cost-effectiveness, and aesthetic appeal of the chip when selecting materials.

“The materials used greatly impact the quality and feel of a casino chip.”

Casino Chip Design

The aesthetic appeal of casino chips plays a major role in the gaming experience. From the color combinations to the intricate designs, every aspect of the chip is thoughtfully considered during the production process.

The first step of designing a casino chip is deciding on the artwork. Many casinos choose to incorporate their logo or specific branding elements into the chip design. Once the artwork is finalized, the manufacturer will determine the placement and color of the design elements. The colors used must be easily distinguishable, and the artwork must be clear and concise.

There are a variety of manufacturing techniques used to create unique, visually appealing designs on the chips. One of the most popular techniques is the use of edge spots – markings on the edge of the chip that differentiate it from other denominations. Another technique is the injection of a molded graphic directly onto the chip surface, providing a raised texture for a more tactile experience.

Overall, the design of a casino chip is as important as its functionality. It enhances the gaming experience and adds to the overall atmosphere of the casino floor.

“Casino chips are not only for practical purposes; they are also works of art.” – Steve Wynn, American businessman and casino developer.

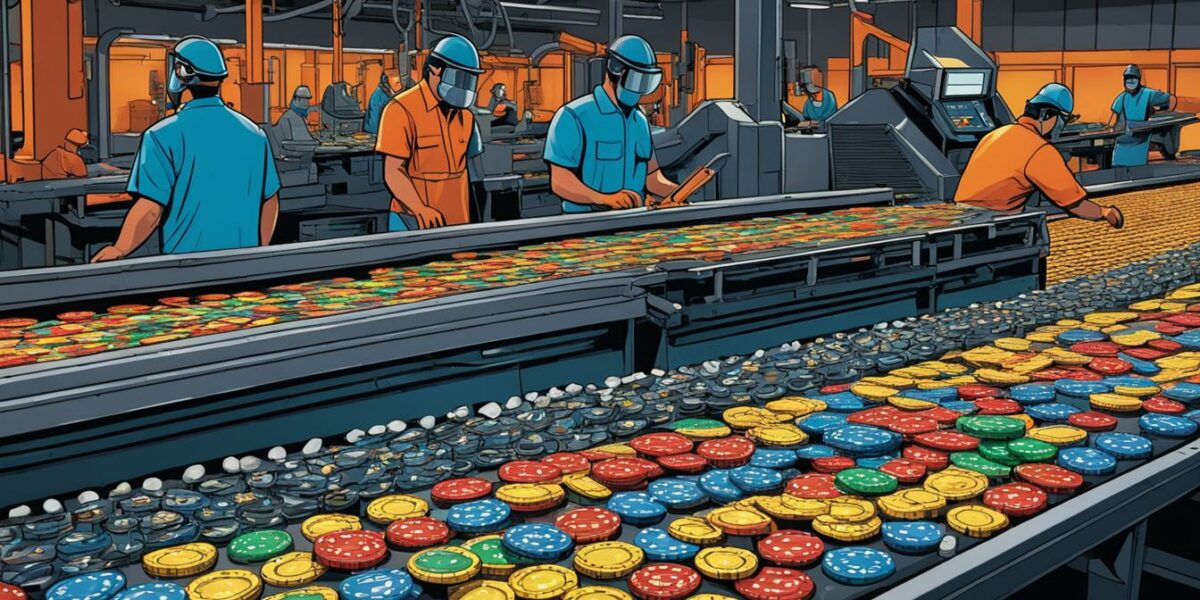

The Casino Chip Manufacturing Process

Producing casino chips involves a series of intricate steps that require precision and expertise. From the moment a casino submits a chip design to the manufacturer, to the final product, every stage of the process is critical in ensuring that the chips are of high quality and meet the exact specifications of the customer.

The first step is the creation of the mold. A mold is designed based on the chip’s specifications, which include the size, weight, and color. The mold is created using special machinery that ensures that every detail of the chip design is captured accurately.

Next, the material for the chips is prepared. A mix of materials, such as clay and ceramic, are blended together in precise proportions to form the base material of the chips. The material is then cut into small pieces and fed into a compression molding machine where it is compressed under high pressure to create the shape of the chips.

Once the chips are formed, they are dried and then fired in a kiln at extremely high temperatures to give them durability and strength. After firing, the chips are polished and then undergo a quality control check to ensure that they meet the required standards.

Finally, the chips are sent to the customer for packaging and distribution. It is important to note that manufacturing casino chips is a highly regulated industry, and manufacturers must comply with strict quality control measures and security standards. This ensures that the chips are not easily counterfeited and that they maintain their value in the casino’s ecosystem.

Overall, the casino chip manufacturing process involves several complex stages that require skill, precision, and attention to detail. It showcases the manufacturing industry’s ability to meet the strict requirements and regulations of the gambling industry, providing casinos with high-quality chips that ensure an authentic gaming experience for players.

Ensuring Quality and Security

Quality control and security measures are critical factors in the manufacturing of casino chips, ensuring that the chips meet the required standards. The manufacturing process undergoes several checks and balances to maintain consistency in the final product.

To maintain quality control, manufacturers take necessary steps to ensure that the manufacturing process remains consistent throughout by conducting regular audits and inspections. They also implement measures to reduce defects, such as using automated systems to detect irregularities in the chips or visually examining each chip to ensure that there are no cracks or imperfections.

Furthermore, security remains a paramount concern in the casino chip manufacturing industry, as it is necessary to prevent counterfeit chips from infiltrating the market. Manufacturers address this issue by using advanced technologies, such as RFID chips, which contain unique identification numbers, to prevent counterfeiting. Manufacturers also make use of tamper-evident packaging to prevent chips from being tampered with and prevent unauthorized access.

By ensuring quality control and implementing sound security measures, chip manufacturers maintain the credibility of their products, which helps to enhance the customer experience and ensures that the industry remains free of fraudulent activities.

Conclusion

Knowing how casino chips are made gives a fascinating insight into the meticulous process and attention to detail involved. By examining the materials, design, manufacturing process, and quality control measures, it’s evident that casino chips are much more than just tokens of currency in the gambling industry.

The use of high-quality materials, intricate designs, and strict security measures ensures that casino chips are not only durable but also authentic. The industry’s regulations and standards make it challenging for counterfeiters to recreate chips, ensuring the integrity of games.

Overall, the casino chip manufacturing process is a fascinating facet of the gambling industry. From the initial design concept to the final product, each step requires precision and care. Despite being small in size, casino chips play a significant role in the gaming world and add to the overall experience.

Thank you for reading our article on how casino chips are made. We hope you found it informative and engaging.

Are Casino Chips Used in Mobile Casino Games Made the Same Way as Traditional Casino Chips?

Yes, top mobile casino games often use casino chips that are made the same way as traditional casino chips. They are typically made from a combination of materials such as clay, ceramic, and plastic to ensure durability and authenticity. These chips are an essential part of the gaming experience, whether in a physical casino or on a mobile platform.

FAQ

How are casino chips made?

Casino chips are made through a multistep manufacturing process that involves designing, molding, and finishing. The process begins with creating a design concept, which is then transferred onto a master mold. Once the master mold is created, it is used to produce multiple molds, which are filled with the chosen material, typically a blend of clay and resin. The filled molds are then compressed, and the excess material is removed. The chips are then subjected to a drying process and undergo finishing touches such as edge alignment and inlay insertion. Finally, a protective coating is applied to enhance durability and longevity.

What materials are used in casino chip fabrication?

Casino chips are typically made using a combination of clay and resin. This blend provides the chips with a solid weight and a satisfying feel. The clay used is often a mix of clay minerals, such as kaolin, mixed with water and other additives. Resin is added to enhance durability and provide flexibility during the molding process. The ratio of clay to resin can vary depending on the desired chip weight and quality.

What considerations are involved in casino chip design?

Casino chip design involves several factors, including aesthetics, functionality, and security. Designs must be visually appealing and should incorporate various elements such as colors, patterns, and images that reflect the casino’s branding. Functionality is crucial, with designs needing to feature easily distinguishable denominations and edge designs that facilitate stacking. Additionally, security measures such as ultraviolet ink, microprinting, and holograms may be incorporated to prevent counterfeiting.

What is the casino chip manufacturing process?

The casino chip manufacturing process begins with the creation of a master mold, usually made from metal or ceramic. The master mold is used to produce multiple molds, also known as dies. These dies are then filled with the chosen chip material, typically a clay-resin blend. Once filled, the molds are compressed, excess material is removed, and the chips undergo a drying process. Additional steps include edge alignment, inlay insertion, and the application of protective coatings. The chips are then inspected, sorted, and packaged for distribution.

How do manufacturers ensure the quality and security of casino chips?

Manufacturers employ various quality control measures to ensure that casino chips meet the required standards. These measures include meticulous inspection and testing at every stage of the manufacturing process, from material selection to finishing touches. In terms of security, manufacturers may incorporate special features such as RFID tags, serial numbers, or unique design elements that are difficult to replicate. Regular audits and monitoring are also conducted to detect any potential security vulnerabilities.